According to which criteria are plastic cards, the ones in your wallets, produced? The smart cards used routinely are products that have to comply with ISO standards, which standardise the size and function of the card.

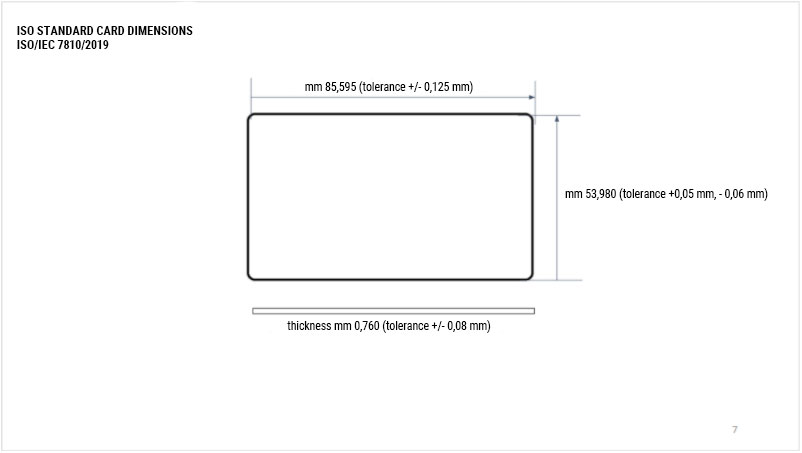

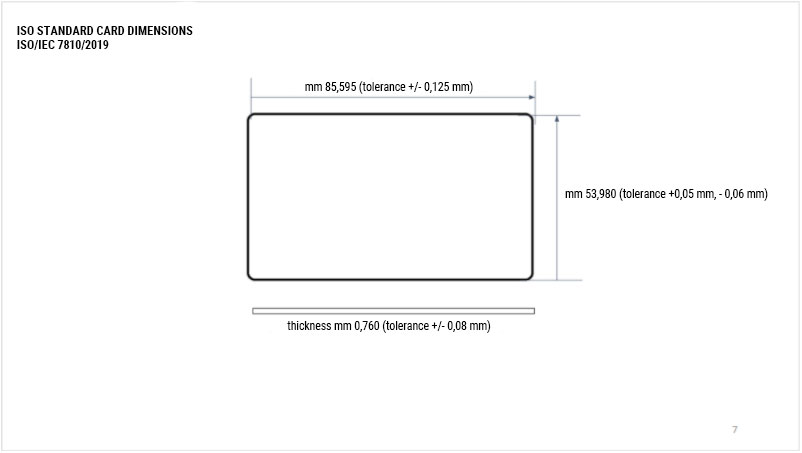

The first reference standard is ISO 7810-2019, which says that the card must be produced with the following dimensions:

- width: 85.595 mm (tolerance +/- 0.125 mm)

- height: 54.980 mm (tolerance +0.05 mm -0.06 mm)

- thickness: 0.760 mm (tolerance +/- 0.08 mm)

Another reference standard is ISO 7816.1, which standardised the mechanical qualities of the card:

- resistance to bending and twisting in accordance with the ISO 7816.1 standard

- thermal shock resistance (160 cycles in the range of -35ºC and +50ºC for 10 minutes)

Cards can also have different thicknesses that do not meet ISO standards. Some examples are given below:

- 20/100

- 30/100

- 40/100

- 50/100

- 60/100

At our production facilities, all plastic cards are measured with certified micrometers and gauges. The measurement instruments are certified through the ISO 9001-2015 company manual. Other tests are carried out using machines specifically designed for these activities.

There are also other standards that regulate the card functions, namely:

- ISO 7816, which governs contact card functioning and chip position;

- ISO 7811-6:2018, which defines the position and characteristics of the magnetic stripe.

Partitalia has the necessary quality verification tools for each of these standards.