Discover the many benefits derived from the implementation of industrial RFID tags.

INDUSTRIAL RFID TAGS

Industrial RFID tags provide valuable information about each individual item throughout its lifecycle, from production entry to final delivery to the customer. RFID hard tags and RFID labels for industry are applied or embedded directly on the product, on metallic and non-metallic objects, or on containers used for the transport and handling of the product itself, such as baskets for handling goods, trolleys, and pallets.

The use of RFID technology enables the optimisation of production processes across various industrial sectors, from mechanical engineering to automotive, as well as food and energy industries, offering a range of tangible benefits.

- Real-time monitoring. RFID tags and RFID labels for industry allow for real-time monitoring of the progress of operations, tracking the path of each product within the production line. This enables the optimisation of production times, identification of batches, and timely intervention in case of anomalies.

- Traceability and authenticity. The information stored within the tags ensures complete traceability and authenticity of the product, from raw materials to finished products. This helps combat counterfeiting and protect brand reputation.

- Optimal warehouse management. RFID technology facilitates warehouse management by providing complete visibility of stock and optimising reordering processes.

- Preventive maintenance. RFID tags and RFID labels for industry can be used to plan preventive maintenance activities, monitoring the wear of machinery and scheduling interventions based on actual needs.

- Security of RFID tags. RFID tags can be applied to goods and equipment to monitor their location and movement in real time. This allows for the quick identification of lost or stolen items and facilitates their recovery.

FIND OUT MORE ABOUT RFID HARD TAGS AND RFID LABELS FOR INDUSTRY

RFID tags for industrial applications

The use of RFID tags - such as RFID hard tags for industrial tracking or custom RFID labels for industrial use - extends to various sectors, optimizing processes, improving security, and opening new avenues for innovation.

Power industry

RFID hard tags for power industry and RFID labels for power industry enable the monitoring of outdoor installations, tracking of cables and pipes, inventory management, and preventive maintenance.

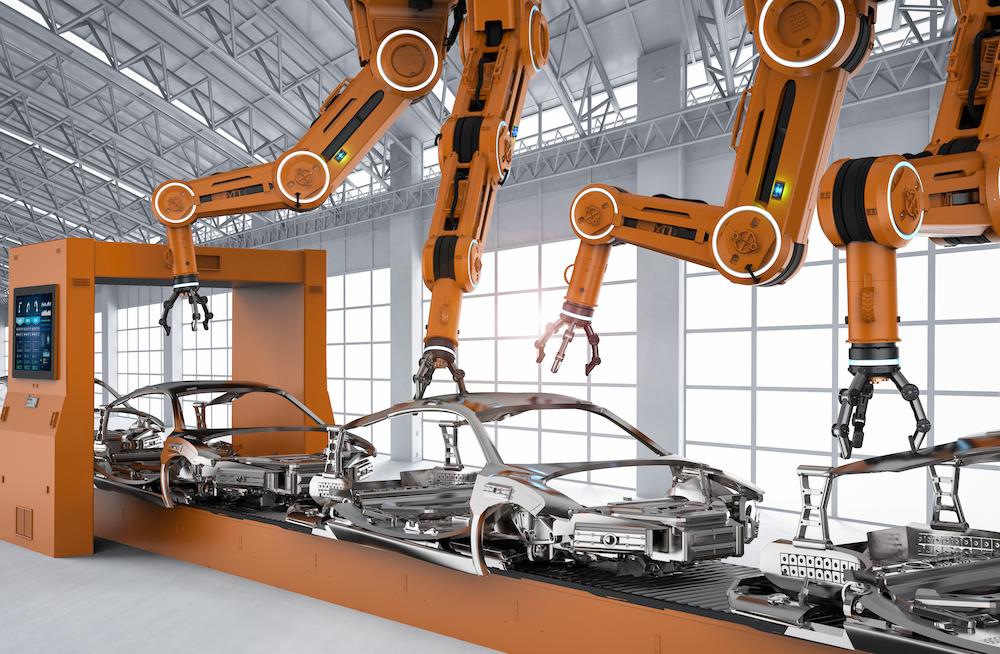

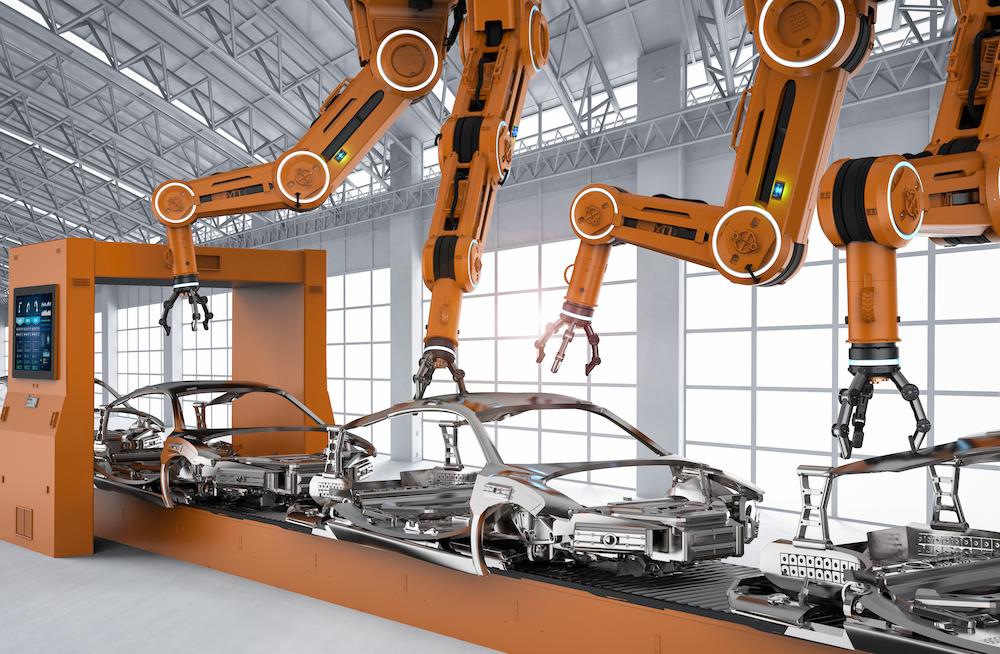

Automotive

RFID tags for automotive manufacturing - for example RFID hard tags for automotive industry and RFID labels for automotive industry - are ideal for quality control, logistics optimisation, reducing errors during assembly and inventory management.

Engineering industry

RFID hard tags for engineering industry and RFID labels for engineering industry are used for tracking the production process, automatic machine setup, and tool inventory management. Partitalia offers the best RFID hard tags for engineering industry.

Pharmaceutical industry

RFID hard tags for pharmaceutical industry and RFID labels for pharmaceutical industry facilitate the RFID traceability of drugs throughout the supply chain. For example, RFID labels for pharmaceutical packaging optimise the industrial processes or are used for monitoring medications to control the cold chain and to ensure product integrity.

Food industry

To ensure hygienic control in production, food traceability, contamination prevention, and food safety, the ideal solutions are RFID labels for food industry and RFID hard tags for food industry.

DISCOVER THE BEST RFID TAGS FOR INDUSTRIAL APPLICATIONS

Choosing the right RFID tags and labels

The choice of RFID hard tags for industry and RFID labels best suited to specific needs depends on several factors, including:

- Shape, size, and materials of the tags: Partitalia’s RFID tags are available in different shapes and materials (adhesive paper or thermoplastic materials such as PVC, PP, or PET), with specific technical characteristics to withstand extreme temperatures, impacts, vibrations, and chemicals.

- Usage environment: It is essential to consider whether the environment is indoor or outdoor to select RFID tags with appropriate resistance to water, dust, and electromagnetic interference.

- Reading distance: The reading distance of RFID tags varies depending on the frequency used and the power of the RFID reader.

- Memory and storage capacity: The amount of data to be stored on the RFID tag influences the choice of chip and memory.

- Communication standards: There are various RFID communication standards, and it is important to choose an RFID tag that is compatible with the existing or planned reading and writing system.

FAQs industrial RFID tags

What are industrial RFID tags used for?

Industrial RFID tags are used for automated identification and data capture. They enable real-time tracking of assets, inventory, and supply chain processes. Common applications include asset management, supply chain visibility, and process optimization.

How do RFID hard tags benefit the power industry?

RFID hard tags benefit the power industry by enabling precise asset tracking, facilitating real-time monitoring of equipment, enhancing maintenance processes and ensuring compliance with safety regulations. Additionally, their durability ensures performance in harsh environments, contributing to overall reliability and effectiveness in power generation and distribution.

What are the advantages of using RFID hard tags in the automotive industry?

RFID hard tags offer several advantages in the automotive industry, including improved quality control through precise tracking of components throughout the production process. They enhance logistics efficiency by optimising inventory management and reducing errors in assembly. Their robustness ensures reliability in demanding environments, contributing to overall operational efficiency and product integrity.

Can RFID hard tags be used in harsh industrial environments?

Yes, RFID hard tags are specifically designed to withstand harsh industrial environments. They are constructed from durable materials that resist extreme temperatures, moisture, dust, and chemical exposure. This robustness ensures reliable performance in challenging conditions, making them suitable for applications in sectors such as manufacturing, energy, and automotive.

How do RFID hard tags improve traceability in the engineering industry?

RFID hard tags enhance traceability in the engineering industry by providing unique, digital identities to assets. These tags can be read remotely, enabling real-time tracking of equipment, components, and materials throughout the entire production process. This improves inventory management, reduces errors, and optimizes supply chain efficiency.

What are RFID labels, and how are they used in industries?

RFID labels are tags that contain an integrated circuit and an antenna. When placed on an object, these tags can be read by an RFID reader to uniquely identify that item. They are used in various industries for tracking and managing assets, inventory, and supply chains. For example, they can be used to track tools in a manufacturing plant, monitor the movement of goods in a warehouse.

How do RFID labels enhance the pharmaceutical industry’s supply chain?

RFID labels revolutionize pharmaceutical supply chains by providing real-time visibility into product movement. These tags offer unique digital identities for each item, enabling accurate tracking from manufacturing to the end consumer. This enhances inventory management, prevents counterfeit drugs, and ensures product quality.

Are RFID tags and labels suitable for food industry tracking?

Absolutely, RFID tags and labels are suited for tracking in the food industry. They offer real-time visibility into product movement, from farm to fork, ensuring food safety and compliance with regulations. This helps to prevent food contamination, recalls, and supply chain disruptions.

What is the difference between RFID hard tags and RFID labels for industrial applications?

RFID hard tags and labels, while both used for identification and tracking, have distinct characteristics. Hard tags are typically more durable and robust, designed for harsh industrial environments. Labels, on the other hand, are generally more flexible and can be attached to a variety of surfaces. The choice between hard tags and labels depends on the specific application, considering factors such as the environment, the item being tracked, and the required read range.

How durable are RFID hard tags in extreme industrial conditions?

RFID hard tags are designed to withstand extreme industrial conditions. They are constructed with durable materials and robust enclosures to protect the electronic components from harsh environments. Factors such as temperature extremes, humidity, chemicals, and mechanical stress are considered during the manufacturing process. However, the specific durability of a hard tag will depend on the exact materials used and the manufacturer's specifications.

How do RFID labels benefit the power industry?

RFID labels offer significant advantages to the power industry by providing real-time asset tracking and management. These tags can be attached to various equipment, such as transformers, circuit breakers, and meters.

How do RFID labels help in inventory management for the automotive industry?

RFID labels revolutionize inventory management in the automotive industry by providing real-time visibility into component and vehicle movement. These tags offer unique digital identities for each item, enabling accurate tracking from raw materials to finished vehicles.

Are RFID tags and labels compatible with industrial automation systems?

Absolutely, RFID tags and labels are highly compatible with industrial automation systems. By leveraging RFID's ability to uniquely identify and track items, industries can enhance efficiency, reduce errors, and improve overall operational performance.